Here is a shot of my electrician chalking out where he will put the can lights for the live room ceiling.

Moderators: Aaronw, John Sayers

I think that was me! At least, that's my philosophy, but I bet I'm not the first person to say it, so I can't claim copyright!"You should design your room around your speakers." Or something very similar to this. My apologies for not remembering who said this.

Panel traps have to be sealed, yes, but I don't understand how yours will work, since they seem to be angled across the corner, and therefore the cavity depth is not constant: So how is that going to work? What frequency did you tune them to? I'm not aware of any theoretical basis for how such a trap would work, or how you would go about tuning it, so I'm intrigued about how you did that! Maybe you could explain?This is the start of the back right base trap in my back wall of my control room. This is a modified design based on Ethan Winer's sealed panel traps.

Hangers are great, but yours seem to be touching each other, so they won't be working too well either. You might want to try strapping thin insulation closer to the board, so that they don't touch each other. Maybe wrap them with wire, or some such. Unless the hangers are able to swing freely, with air gaps between them, then they'll just act like expensive absorbers, not like hangers. You also should put some absorption on the rear wall, behind the hangers. That's part of the system.In addition to my corner panel traps I also added "hanger" base traps as described by John here on the forum.

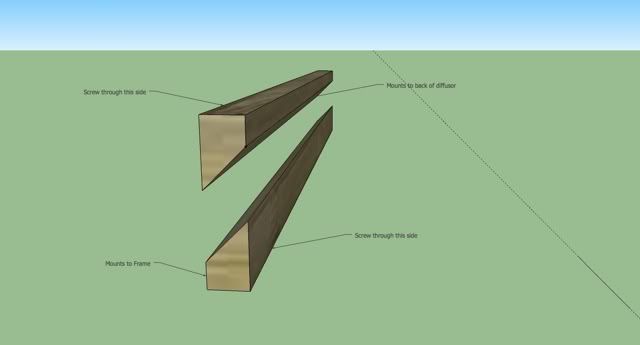

Are those N7 QRD's? Looks like they might be. What is the low frequency cutoff for those? Looks like they go down fairly low.This was exciting to finally mount these diffusors onto the wall.