New build, isolation req. Control room enviroment

-

Purelythemusic

- Posts: 56

- Joined: Wed May 30, 2018 7:31 am

- Location: England, Bristol

- Contact:

New build, isolation req. Control room enviroment

Hi all,

I've read many good resources and built a budget control room environment which turned out well but it didn't require isolation. I'll continue to research here for the various parts of the build, but I thought it would be great to have some initial feedback before I submit a planning application for the general plan. I'll try to be as brief as possible!

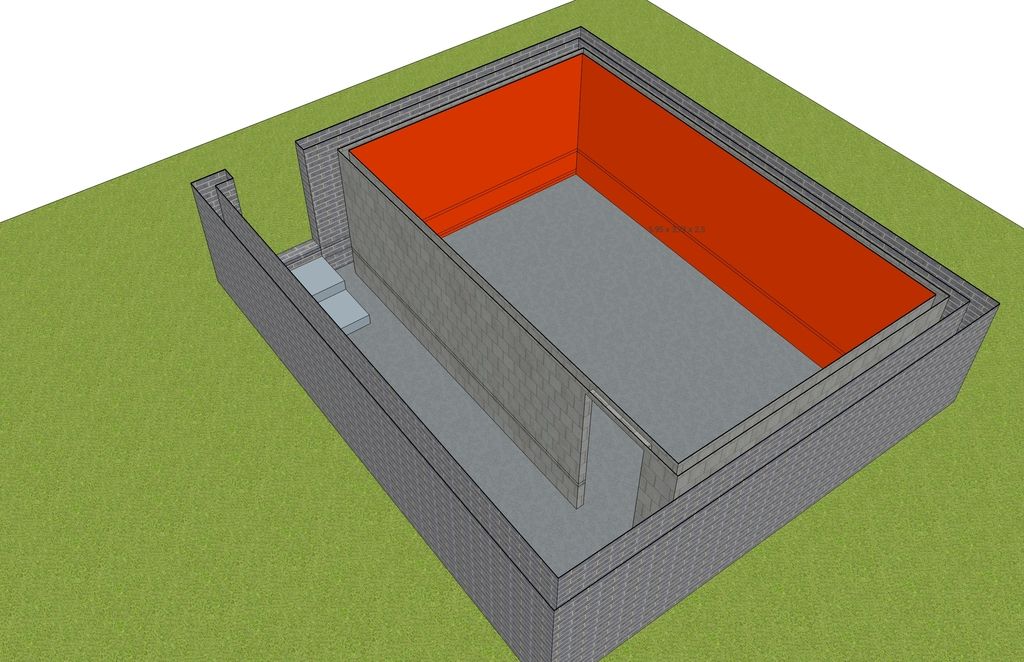

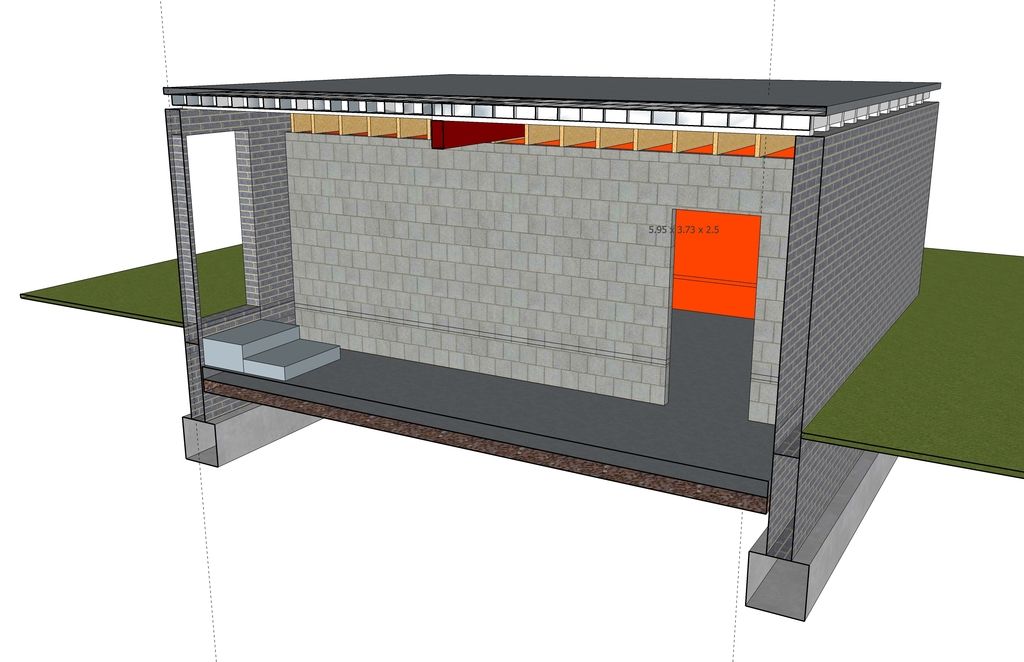

I am building a detached garage looking outbuilding and I would like it to appear as such although without a garage door.

I need a sound isolated room within which I plan to build a decoupled, well treated room for a 1 room studio. Within the same building, some tool storage.

Plan is to build a solid mass structure, using concrete blocks on their belly/flat (215mm (w) x 100mm (h))...ceiling undefined as yet possibly concrete, possibly isolate the floor slab from the walls.

Outside of it on three sides have 100mm cavity with normal fluffy fibreglass cavity insulation and on one long side have 1.5m cavity/space for tool storage and ventilation equipment etc. Outermost leaf build out of concrete blocks on their edge (normal 100mm (w) x 215mm (h), outer leaf to have normal flat roof design, not touching the inner big mass structure, except at the foundation concrete and adjoining soil.

The inner true room (concrete blocks on flat - where reflections will happen and hopefully very little flex/transmission) will be 1:1.50:2.50 or one of the other similar sized recommended ratios to try to start with best case modal resonance.

The internal size of the true room is: 2.6m 8.53ft (H) x 3.9m 12.79ft (w) x 6.5m 21.32ft (L)

Angle the rooms' long walls slightly as per Wes' design on real traps website as I don't have space for 35 degrees or more to have a live front end. I'm open : ) to having a basic rectangle...easier to build but angling the walls slightly does seem to make sense if you are bass trapping the whole back wall.

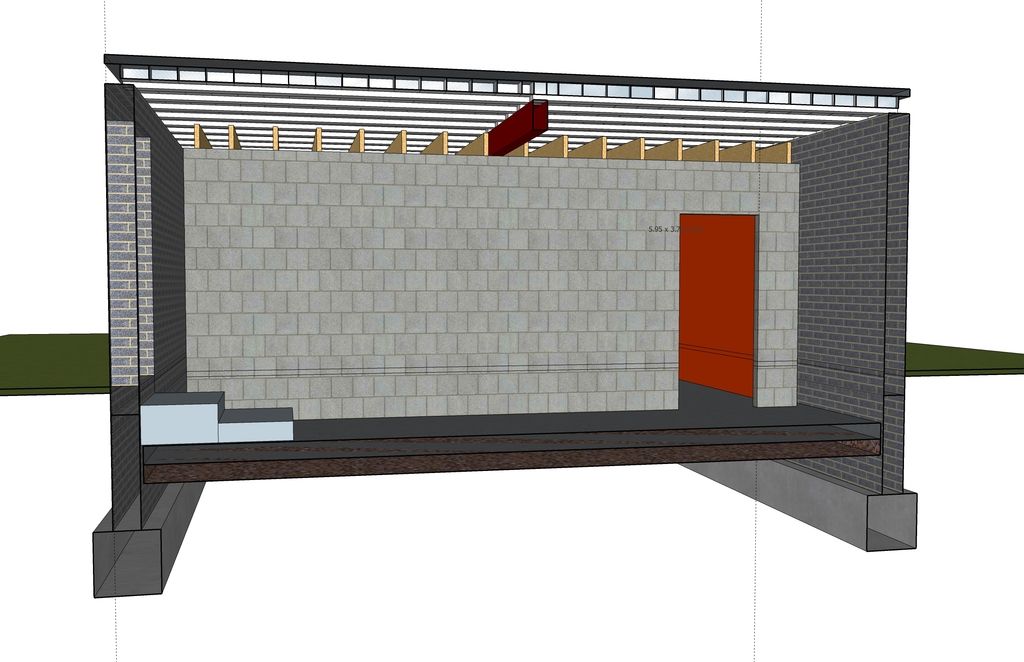

The innermost room I haven't given lots of thought to yet but first thoughts are that it would be decoupled timber framed, either built off insulation with floating ply floor, or rubber feet, with 100mm (4") space (cavity) all around filled with fluffy insulation from the back of the drywall up to the true wall (block on flat wall), then on the inside one sheet of drywall 1/2" hopefully creating 1 level of bass trapping.

Planning to build the back wall off with more space (750mm) to create 1 large Bass Traps topped with diffusers. Treatment inside the room to have completely absorbent ceiling (100mm Rockwool RW7) with possibly some reflection around the perimeter. The usual mid-high absorbers at all remaining first reflection zones.

Thanks for your patience reading this far : )

Budget, somewhere around £20k I'm the builder along with a couple of mates.

Questions:

Are there any major flaws with the basic isolation plan...Thick walled and ceiling with cavity outside, then final skin of masonry?

Would it be that necessary to try to separate the floor slab from the walls?

Any bright ideas to create a high mass ceiling without using concrete?

I've read many good resources and built a budget control room environment which turned out well but it didn't require isolation. I'll continue to research here for the various parts of the build, but I thought it would be great to have some initial feedback before I submit a planning application for the general plan. I'll try to be as brief as possible!

I am building a detached garage looking outbuilding and I would like it to appear as such although without a garage door.

I need a sound isolated room within which I plan to build a decoupled, well treated room for a 1 room studio. Within the same building, some tool storage.

Plan is to build a solid mass structure, using concrete blocks on their belly/flat (215mm (w) x 100mm (h))...ceiling undefined as yet possibly concrete, possibly isolate the floor slab from the walls.

Outside of it on three sides have 100mm cavity with normal fluffy fibreglass cavity insulation and on one long side have 1.5m cavity/space for tool storage and ventilation equipment etc. Outermost leaf build out of concrete blocks on their edge (normal 100mm (w) x 215mm (h), outer leaf to have normal flat roof design, not touching the inner big mass structure, except at the foundation concrete and adjoining soil.

The inner true room (concrete blocks on flat - where reflections will happen and hopefully very little flex/transmission) will be 1:1.50:2.50 or one of the other similar sized recommended ratios to try to start with best case modal resonance.

The internal size of the true room is: 2.6m 8.53ft (H) x 3.9m 12.79ft (w) x 6.5m 21.32ft (L)

Angle the rooms' long walls slightly as per Wes' design on real traps website as I don't have space for 35 degrees or more to have a live front end. I'm open : ) to having a basic rectangle...easier to build but angling the walls slightly does seem to make sense if you are bass trapping the whole back wall.

The innermost room I haven't given lots of thought to yet but first thoughts are that it would be decoupled timber framed, either built off insulation with floating ply floor, or rubber feet, with 100mm (4") space (cavity) all around filled with fluffy insulation from the back of the drywall up to the true wall (block on flat wall), then on the inside one sheet of drywall 1/2" hopefully creating 1 level of bass trapping.

Planning to build the back wall off with more space (750mm) to create 1 large Bass Traps topped with diffusers. Treatment inside the room to have completely absorbent ceiling (100mm Rockwool RW7) with possibly some reflection around the perimeter. The usual mid-high absorbers at all remaining first reflection zones.

Thanks for your patience reading this far : )

Budget, somewhere around £20k I'm the builder along with a couple of mates.

Questions:

Are there any major flaws with the basic isolation plan...Thick walled and ceiling with cavity outside, then final skin of masonry?

Would it be that necessary to try to separate the floor slab from the walls?

Any bright ideas to create a high mass ceiling without using concrete?

-

Soundman2020

- Site Admin

- Posts: 11938

- Joined: Thu Aug 21, 2008 10:17 am

- Location: Santiago, Chile

- Contact:

Re: New build, isolation req. Control room enviroment

Hi there "Purelythemusic", and Welcome!

I'm not quite sure that I understand your plan, and your diagrams aren't helping me much to get it: I'm not sure if I am seeing 2 wallsm three walls, four walls, five walls, or six walls! So I'll work through your post piece by piece with comments, then see where we get, and hopefully get you on the right track:

TL = 14.5 log (Ms * 0.205) + 23 dB

Where: M = Surface Mass in kg/m2

If you do the math, using the density of concrete, you'll find that a single wall doesn't provide much isolation at all.

That said, if you decide to build your control room following the RFZ concept, then you will need to add angled surfaces WITHIN the room to achieve that, but they are not part of the wall: the walls are still rectangular.

Splaying walls wastes space, and is not necessary, except in exceptional circumstances.

OK, lets go back to basics: You are way over-thinking this, and your plan so far stands a really good chance of costing you LOTS of money to build, for not.so-much benefit.

The normal procedure when designing a studio is to first of all define how much isolation you need, in decibels. It's very easy to do, and VERY necessary. If you don't know how much isolation you need, then you cannot design something to achieve that! It's like saying "I want to go on vacation", but not know where you are going, how far you are going, how long you are going to stay or how you are going to get there!

The simplest, least expensive, most effective method for building typical home studios is called "fully-decoupled 2-leaf MSM". What that means is that you have one single outer "leaf" around your entire building, and within that shell you build each room as it's own independent singe-leaf structure. That's it. Not complicated. IF you try to do the same with a 3-leaf, 4-leaf or n-Leaf, then the low frequency isolation will be WORSE, unless you compensate, which requires a lot more money and space. The same happens if you try to do one single leaf ("Mass Law"). Pretty much all studios are built as 2-leaf MSM systems these days. It just makes sense.

However, in order to know what building materials you need and what construction technique you need for this, you MUST first know how much isolation you need. You can't just guess and hope it will work: if you guess, there are only three possible outcomes: 1) You "under-guess", and the finished building does not provide enough isolation, sounds terrible, and is basically useless. 2) You "over-guessed", the finished building DOES isolate well enough, but you spent 5 times more than you needed to. 3) Purely by the best stroke of luck you ever had in your life, you just happened to get it right by sheer chance. The possibilities of that happening are about the same as you winning every jackpot in the country on the same day, then getting struck by lightning and surviving without a scratch... In other words: about zero.

So, once you have determined the amount of isolation you need, in decibels, it's a simple matter to look at the types of construction that will get you that amount, then decide which one you prefer, or which one you can afford.

Acoustics is a science: sound is fairly well understood. Three are equations that describe how it moves, and how it interacts with various different types of materials. By combining those materials in simple ways that follow the equations, you can get the results you want.

For example, here's a thread about a studio that a customer of mine has built, and we are now in the process of "tuning" the control room: http://www.johnlsayers.com/phpBB2/viewt ... 68&start=0 I designed that a couple of years back, he has almost completed it, and the tuning is going on right now. In that thread, you can see exactly how the process works, starting out with the bass trapping.

Here's another example, from a different customer, of a completed studio, after the control room has been tuned to perfection: http://www.johnlsayers.com/phpBB2/viewt ... =2&t=20471

All of that is being achieved by following the laws of acoustics, and the known properties of sound, and how it interacts with objects.

What you are proposing is not going to work the way you are hoping. And that word itself is already a problem: "hoping" that something will work in your studio is a bad idea: its far better to DESIGN it so that it WILL work, rather than guessing and hoping.

Bass traps are used for a reason. Diffusers are used for a reason. If you don't know what those reasons are and still want to use them, then it's very, very likely that they won't do what is needed in the room.

There's a document knows as ITU BS-1116.3 that lays out all of the acoustic specifications that a room should meet in order to be usable as a "critical listening" room. Everything you do in designing and treating your room should be done for the exact purpose of meeting one or more of those specifications.

These are all things that you need to consider when designing your room. Everything you put in there should have a defined purpose.

So I'd suggest that you should start out by determine how much isolation you actually need, then taking it from there.

- Stuart -

I'm not quite sure that I understand your plan, and your diagrams aren't helping me much to get it: I'm not sure if I am seeing 2 wallsm three walls, four walls, five walls, or six walls! So I'll work through your post piece by piece with comments, then see where we get, and hopefully get you on the right track:

You'll use up a lot of concrete blocks like that, for not such a good result. There's a principle of physics called "Mass Law" which describes how much isolation you can get from a purely massive barrier: It's not as much as you think. Not even close. The actual equation goes like this:Plan is to build a solid mass structure, using concrete blocks on their belly/flat (215mm (w) x 100mm (h))..

TL = 14.5 log (Ms * 0.205) + 23 dB

Where: M = Surface Mass in kg/m2

If you do the math, using the density of concrete, you'll find that a single wall doesn't provide much isolation at all.

How would you do that? Are you talking about an isolated slab build, or a floating floor within the walls? There are several ways of doing that, all of them expensive, all of them hard to do properly, and you very likely don't need any of them anyway...possibly isolate the floor slab from the walls.

Is that the SAME wall you are describing above? Or a DIFFERENT wall?Outermost leaf build out of concrete blocks on their edge (normal 100mm (w) x 215mm (h),

What "the inner true room" is that? I'm having a hard time keeping track of which rooms are where, and which walls are what...The inner true room

What do you mean by "flex" there?concrete blocks on flat - where reflections will happen and hopefully very little flex/transmission

Just checking: This is ONLY a control room, right? It won't be a dual-purpose room? No tracking? Not also a "home theater"? No band rehearsal / jamming? The reason for the question is that 25m2 floor area is great for a control room, but small if you wanted to use this as for some other purpose.The internal size of the true room is: 2.6m 8.53ft (H) x 3.9m 12.79ft (w) x 6.5m 21.32ft (L)

Actually, that's a myth. A very well propagated myth, rebounding around the internet all the time, but a myth nevertheless. Angling or "splaying" your side walls offers no advantages for modal response, and no advantages for bass control either. Splaying the walls is ONLY useful for dealing with something called "flutter echo", but there are much simpler ways to deal with that. The best shape for a control room is a simple rectangle. It's also the easiest and cheapest to build.Angle the rooms' long walls slightly as per Wes' design on real traps website as I don't have space for 35 degrees or more to have a live front end. I'm open : ) to having a basic rectangle...easier to build but angling the walls slightly does seem to make sense if you are bass trapping the whole back wall.

That said, if you decide to build your control room following the RFZ concept, then you will need to add angled surfaces WITHIN the room to achieve that, but they are not part of the wall: the walls are still rectangular.

Splaying walls wastes space, and is not necessary, except in exceptional circumstances.

ANOTHER "innermost room"??? How many "innermost rooms" are there???The innermost room I haven't given lots of thought to yet but first thoughts are that it would be decoupled timber framed,

OK, lets go back to basics: You are way over-thinking this, and your plan so far stands a really good chance of costing you LOTS of money to build, for not.so-much benefit.

The normal procedure when designing a studio is to first of all define how much isolation you need, in decibels. It's very easy to do, and VERY necessary. If you don't know how much isolation you need, then you cannot design something to achieve that! It's like saying "I want to go on vacation", but not know where you are going, how far you are going, how long you are going to stay or how you are going to get there!

The simplest, least expensive, most effective method for building typical home studios is called "fully-decoupled 2-leaf MSM". What that means is that you have one single outer "leaf" around your entire building, and within that shell you build each room as it's own independent singe-leaf structure. That's it. Not complicated. IF you try to do the same with a 3-leaf, 4-leaf or n-Leaf, then the low frequency isolation will be WORSE, unless you compensate, which requires a lot more money and space. The same happens if you try to do one single leaf ("Mass Law"). Pretty much all studios are built as 2-leaf MSM systems these days. It just makes sense.

However, in order to know what building materials you need and what construction technique you need for this, you MUST first know how much isolation you need. You can't just guess and hope it will work: if you guess, there are only three possible outcomes: 1) You "under-guess", and the finished building does not provide enough isolation, sounds terrible, and is basically useless. 2) You "over-guessed", the finished building DOES isolate well enough, but you spent 5 times more than you needed to. 3) Purely by the best stroke of luck you ever had in your life, you just happened to get it right by sheer chance. The possibilities of that happening are about the same as you winning every jackpot in the country on the same day, then getting struck by lightning and surviving without a scratch... In other words: about zero.

So, once you have determined the amount of isolation you need, in decibels, it's a simple matter to look at the types of construction that will get you that amount, then decide which one you prefer, or which one you can afford.

A floating floor is a bad idea, and you do NOT need one. Here's why: http://www.johnlsayers.com/phpBB2/viewt ... f=2&t=8173either built off insulation with floating ply floor,

Wellll.... no. It seems you've been reading some of the more curious internet "resources" on studio acoustics, or watching too many YouTube videos... That's not going to help you much. There's a HUGE amount of pure garbage circulating out there about acoustics and studio design, and a very large number of enthusiastic "Look how I'm building my studio" videos, most of which are just plain futile, and many of which are unsafe, illegal, and dangerous.then on the inside one sheet of drywall 1/2" hopefully creating 1 level of bass trapping.

Acoustics is a science: sound is fairly well understood. Three are equations that describe how it moves, and how it interacts with various different types of materials. By combining those materials in simple ways that follow the equations, you can get the results you want.

For example, here's a thread about a studio that a customer of mine has built, and we are now in the process of "tuning" the control room: http://www.johnlsayers.com/phpBB2/viewt ... 68&start=0 I designed that a couple of years back, he has almost completed it, and the tuning is going on right now. In that thread, you can see exactly how the process works, starting out with the bass trapping.

Here's another example, from a different customer, of a completed studio, after the control room has been tuned to perfection: http://www.johnlsayers.com/phpBB2/viewt ... =2&t=20471

All of that is being achieved by following the laws of acoustics, and the known properties of sound, and how it interacts with objects.

What you are proposing is not going to work the way you are hoping. And that word itself is already a problem: "hoping" that something will work in your studio is a bad idea: its far better to DESIGN it so that it WILL work, rather than guessing and hoping.

What type of bass trap? What type of diffuser? What frequency range will the diffuser be tuned to? How big will it be? Why will it be that big, and not smaller? Or bigger?Planning to build the back wall off with more space (750mm) to create 1 large Bass Traps topped with diffusers.

Bass traps are used for a reason. Diffusers are used for a reason. If you don't know what those reasons are and still want to use them, then it's very, very likely that they won't do what is needed in the room.

There's a document knows as ITU BS-1116.3 that lays out all of the acoustic specifications that a room should meet in order to be usable as a "critical listening" room. Everything you do in designing and treating your room should be done for the exact purpose of meeting one or more of those specifications.

What decay time are you shooting for with this plan? Is it consistent with the room size? Will it be even and smooth across the spectrum, or will there be sharp differences in decay between adjacent frequency bands?Treatment inside the room to have completely absorbent ceiling (100mm Rockwool RW7) with possibly some reflection around the perimeter. The usual mid-high absorbers at all remaining first reflection zones.

These are all things that you need to consider when designing your room. Everything you put in there should have a defined purpose.

For the UK, that's in the general ballpark, but probably a little on the low side. Several of my customers in the UK have reported that their final costs for a ground-up build is in the regions of £1,000 to £1,500 per square meter of building footprint. Your estimate is below that, but you do say that you have people who can help out with the build, so you'll be saving on labor there. But even so, I would consider either increasing the budget, or reducing the footprint. You could make the control room smaller and still get excellent results.Budget, somewhere around £20k I'm the builder along with a couple of mates.

See above...Are there any major flaws with the basic isolation plan...

Only if you need VERY high isolation, which is probably not the case. When you are ready, I can walk you through the procedure for defining how much isolation you will need, and absed on that, you can decide if you need an isolated slab, or not.Would it be that necessary to try to separate the floor slab from the walls?

Beam and block. OK, so it still uses concrete, but in the form of pre-cast beams and standard blocks. Simpler than trying to pour your own.Any bright ideas to create a high mass ceiling without using concrete?

So I'd suggest that you should start out by determine how much isolation you actually need, then taking it from there.

- Stuart -

-

Purelythemusic

- Posts: 56

- Joined: Wed May 30, 2018 7:31 am

- Location: England, Bristol

- Contact:

Re: New build, isolation req. Control room enviroment

Hi Stuart!

Wow, Thank you hugely for going through these details with me! Great I'm ready to get into science!

I'll try to answer all things as clearly as possible...

I can't believe I'd not come across Mass Law before!

Yes I do need to work out how much isolation I need...it is alot, I won't be able to use the studio much in work hours or early evening, so assume I wan't to be able to record drums at midnight without anyone knowing I'm there...thats why I have gone a bit over the top on the walls...but it is still a hope that would be nice to design to a certainty...

Yes I was a bit concerned whether I was creating a poly leaf room which I have read is a bad idea... but I thought that sound which does pass through the big thick mass wall will be then airborne in the cavity and finally attenuated by the outer masonry wall.

Ok great, so I'll get researching and work out how much isolation I need!

Wow, Thank you hugely for going through these details with me! Great I'm ready to get into science!

I'll try to answer all things as clearly as possible...

Ha, yes sorry, 3 walls in total, the outer 2 are masonry.I'm not quite sure that I understand your plan, and your diagrams aren't helping me much to get it: I'm not sure if I am seeing 2 wallsm three walls, four walls, five walls, or six walls!

I can't believe I'd not come across Mass Law before!

I was going to use some sort of rubber/compressible foam between the concrete floor slab and the walls before the pour...How would you do that? Are you talking about an isolated slab build, or a floating floor within the walls? There are several ways of doing that, all of them expensive, all of them hard to do properly, and you very likely don't need any of them anyway...

Different wall : )Is that the SAME wall you are describing above? Or a DIFFERENT wall?

Ha, the thick block wall...I called it the true room as I thought that would be where almost all of the sound pressure/waves would be contained within as opposed to the timber framed room inside...What "the inner true room" is that? I'm having a hard time keeping track of which rooms are where, and which walls are what...

I mean transmission really...but flex following the logic in my head that sound travels through objects and air by pushing matter about, so if a wall was solid enough it wouldn't be pushed at all, or flex at all...like a membrane...What do you mean by "flex" there?

Well I will be using it for recording, drums, and other acoustic instruments and thought, although I realise a control room won't be lovely to record in, it's probably better than trying to mix in a room that's a bit too live. It is really the biggest I'll be able to get on the plot next to the large extension we're currently building : )Just checking: This is ONLY a control room, right? It won't be a dual-purpose room? No tracking? Not also a "home theater"? No band rehearsal / jamming? The reason for the question is that 25m2 floor area is great for a control room, but small if you wanted to use this as for some other purpose.

Great, that all makes sense!Splaying walls wastes space, and is not necessary, except in exceptional circumstances.

Yes I do need to work out how much isolation I need...it is alot, I won't be able to use the studio much in work hours or early evening, so assume I wan't to be able to record drums at midnight without anyone knowing I'm there...thats why I have gone a bit over the top on the walls...but it is still a hope that would be nice to design to a certainty...

Yes I was a bit concerned whether I was creating a poly leaf room which I have read is a bad idea... but I thought that sound which does pass through the big thick mass wall will be then airborne in the cavity and finally attenuated by the outer masonry wall.

Great, I'll take a look at those threads... I think I get the gist of it, but will get to grips properly.Acoustics is a science: sound is fairly well understood. Three are equations that describe how it moves, and how it interacts with various different types of materials. By combining those materials in simple ways that follow the equations, you can get the results you want.

Ah nice!There's a document knows as ITU BS-1116.3 that lays out all of the acoustic specifications that a room should meet in order to be usable as a "critical listening" room. Everything you do in designing and treating your room should be done for the exact purpose of meeting one or more of those specifications.

Oh yea, obvious really...we've done block n beam for our extension floor...but using aircrete, so I can just use concerete blocks and grout meticulously : )Beam and block. OK, so it still uses concrete, but in the form of pre-cast beams and standard blocks. Simpler than trying to pour your own.

Ok great, so I'll get researching and work out how much isolation I need!

-

Purelythemusic

- Posts: 56

- Joined: Wed May 30, 2018 7:31 am

- Location: England, Bristol

- Contact:

Re: New build, isolation req. Control room enviroment

Hi all,

So I'm trying to work out how much sound attenuation I actually need, then work out how and if it's possible.

From what I seem to be able to find out, a drum kit may produce something around 130db (bass drum prime suspect), possibly a bit more, unlikely a bit less in my hands...

The ambient noise in my garden is possibly something like rustling leaves, except in the dead of night, so that seems to be around 10db.

The studio will be about 1m from a lane which takes traffic. I would like to prevent traffic noise (and any other noise) from making it into the control room and I would like people walking their dogs down the lane not to hear if I am playing drums.

Am I asking for 120db attenuation?

Am I asking for too much?

As I believe I now understand, even with a fairly massive middle wall in my previously envisioned classic mistake 3 leaf model, I will still cause a bass frequency problem. Perhaps it is better to just build one outer leaf of large mass, then focus on physical separation to isolate the inner room completely from the outer structure.

I'll be searching the threads for a similar decibel ambition : )

So I'm trying to work out how much sound attenuation I actually need, then work out how and if it's possible.

From what I seem to be able to find out, a drum kit may produce something around 130db (bass drum prime suspect), possibly a bit more, unlikely a bit less in my hands...

The ambient noise in my garden is possibly something like rustling leaves, except in the dead of night, so that seems to be around 10db.

The studio will be about 1m from a lane which takes traffic. I would like to prevent traffic noise (and any other noise) from making it into the control room and I would like people walking their dogs down the lane not to hear if I am playing drums.

Am I asking for 120db attenuation?

Am I asking for too much?

As I believe I now understand, even with a fairly massive middle wall in my previously envisioned classic mistake 3 leaf model, I will still cause a bass frequency problem. Perhaps it is better to just build one outer leaf of large mass, then focus on physical separation to isolate the inner room completely from the outer structure.

I'll be searching the threads for a similar decibel ambition : )

-

Soundman2020

- Site Admin

- Posts: 11938

- Joined: Thu Aug 21, 2008 10:17 am

- Location: Santiago, Chile

- Contact:

Re: New build, isolation req. Control room enviroment

This is why it is important to get a sound level meter and actually measure the levels, rather then just looking at numbers from sources that mentioned extremes.

OK, reality time: Your drums will probably be putting out about 105 dB, maybe 115 dB, perhaps a little more. The ambient level outside is likely around 45 dB, so you probably need around 50 to 60 dB of isolation. That is doable, if you have a reasonable budget, design it well, and build it carefully.

There are equations for calculating all of this, and you can use those to predict the performance of pretty much any wall. Or if you don't like math, you can look at research papers such as IR-761 and IR-586 and BRN-217.

- Stuart -

130 dBC is about the level you would hear if you stand behind a 747 at the end of a runway, when it has all four engines running at maximum thrust, as it starts its take-off run. Or the loudest ever rock concert: 129.5 dB in 1984, in Hanover, Germany. Huge towers of multi-stacked speakers, enormous racks of amps, tens of thousands of watts... So it's VERY unlikely that your drum kit will put out 130 dB SPL, when measured correctly. Maybe 115.a drum kit may produce something around 130db

Once again, that's extremely unlikely, unless you live in the middle of a desert, many dozens of miles from the nearest town, with no wind, no life at all around, and you manage to warp yourself in a soundproof jacket. I once measured the sound level in such a place (the Atacama desert), and got around 20 dB, when I had the meter set up a long way from where I was standing, so it would not pick up my heart beat or my breathing. Typical ambient noise levels in very quiet rural areas are about ten times louder (perhaps 30 dB), in suburban areas about a hundred times louder (40 dB), and in inner-city areas, around a thousand times louder (50 dB). You can get a very rough idea of what the REAL ambient level is, by referencing those, but in order to be certain, you need to actually measure it yourself, with a decent quality, accurate, calibrated sound level meter. (Not with an iPhone app.)The ambient noise in my garden is possibly something like rustling leaves, except in the dead of night, so that seems to be around 10db.

At 120 dB, yes. The very best isolated studio on planet Earth is arguably Galaxy Studios, in Belgium. They hired the best acousticians to design the ultimate isolation system, spared no expense, took five years to design and build it, spent several millions of dollars, and managed to achieve the very, very excellent level of a little over 100 dB of isolation. So yes, looking for 120 dB is probably "asking for too much".Am I asking for 120db attenuation? Am I asking for too much?

OK, reality time: Your drums will probably be putting out about 105 dB, maybe 115 dB, perhaps a little more. The ambient level outside is likely around 45 dB, so you probably need around 50 to 60 dB of isolation. That is doable, if you have a reasonable budget, design it well, and build it carefully.

Right! Conceivably, it could be a problem, especially of you tune your kick and floor-tom low, or also have a 6-string bass.As I believe I now understand, even with a fairly massive middle wall in my previously envisioned classic mistake 3 leaf model,

The equations for two-leaf MSM walls are based on having roughly equal mass in both leaves, and laboratory testing has shown that this is the most effective combination. It makes sense, if you think about it: If you had a massive concrete outer leaf and your inner leaf was a sheet of paper, technically that's still a 2-leaf wall, but the isolation would be pretty lousy! It would be pretty much the same as a single-leaf wall. If you increased the mass of the inner-leaf by using thick cardboard, instead of paper, and removed the same amount of mass from the outer leaf, the isolation would be better, but still rather poor! Change it again, by replacing the cardboard with a single sheet of thin drywall, while removing that mass from the out leaf, and things start improving, but still not good. Update that to three layers of thick, heavy drywall on the inner-leaf, removing the same mass from the outer leaf, and now things are looking pretty good. If you keep on down that track, and end up with the same mass on each leaf, you have the optimum situation. In all cases the TOTAL mass is the same, as is the separation between leaves, but the best case is where the two leaves have similar mass.Perhaps it is better to just build one outer leaf of large mass, then focus on physical separation to isolate the inner room completely from the outer structure.

There are equations for calculating all of this, and you can use those to predict the performance of pretty much any wall. Or if you don't like math, you can look at research papers such as IR-761 and IR-586 and BRN-217.

Basically, the more you need, the harder it gets. As a point of reference, a typical stud-framed house wall with drywall on both sides and insulation inside will get you about 30 dB of isolation, which is not much. A 2-leaf stud framed wall with separate frames and 2 layers of drywall on each leaf will get you upwards of 50 dB, which is pretty good. A larger air gap with 3 layers on each side can get you 60 dB or more, it built with great care. The practical limit for home studios (unless you have deep pockets, and great determination), is around 70 dB, which is amazing.So I'm trying to work out how much sound attenuation I actually need, then work out how and if it's possible.

- Stuart -

-

Purelythemusic

- Posts: 56

- Joined: Wed May 30, 2018 7:31 am

- Location: England, Bristol

- Contact:

Re: New build, isolation req. Control room enviroment

Ah, I see, I apologise for my naivety!

I shall buy a calibrated SPL meter and report readings.

Understood also about the mass of each leaf and the cavity depth influencing the resulting attenuation. I’m reading a couple of threads which have some great information and especially how easy it is to get it wrong as I would have! I had a go at calculatung the resonant frequency if the a 2 leaf MSM model based on the density of single skin concrete block wall at 244kg/m2 and blocks on the flat (as per my original true wall : ) which are somewhere around 450kg/m2 but my math knowledge fell short. I did:

Fc = 43[(244 + 244)/(0.1)]^0.5

Fc = 43 x (488/0.1)^0.5

Fc = 43 x 4880 ^ 0.5

Fc = 458

I think I’m misunderstanding a function or two : )

Can you create adequate isolation between the floor slab (100mm compacted type 1 harcore, 20mm sand, DPM, 120mm insulation, VCL then 150mm concrete vibrated) by (as we usually do) build the walls up to the level of the finished slab, then include dense insulation (celotex) around the perimeter say 30mm thick, then remove the perimeter insulation? That would leave an air gap and the inner wall can be built off the slab with the outer wall totally independant?

Thank you for all the valuable help!

I shall buy a calibrated SPL meter and report readings.

Understood also about the mass of each leaf and the cavity depth influencing the resulting attenuation. I’m reading a couple of threads which have some great information and especially how easy it is to get it wrong as I would have! I had a go at calculatung the resonant frequency if the a 2 leaf MSM model based on the density of single skin concrete block wall at 244kg/m2 and blocks on the flat (as per my original true wall : ) which are somewhere around 450kg/m2 but my math knowledge fell short. I did:

Fc = 43[(244 + 244)/(0.1)]^0.5

Fc = 43 x (488/0.1)^0.5

Fc = 43 x 4880 ^ 0.5

Fc = 458

I think I’m misunderstanding a function or two : )

Can you create adequate isolation between the floor slab (100mm compacted type 1 harcore, 20mm sand, DPM, 120mm insulation, VCL then 150mm concrete vibrated) by (as we usually do) build the walls up to the level of the finished slab, then include dense insulation (celotex) around the perimeter say 30mm thick, then remove the perimeter insulation? That would leave an air gap and the inner wall can be built off the slab with the outer wall totally independant?

Thank you for all the valuable help!

-

Purelythemusic

- Posts: 56

- Joined: Wed May 30, 2018 7:31 am

- Location: England, Bristol

- Contact:

Re: New build, isolation req. Control room enviroment

Well I've just finished the Drum room thread, which was a difficult and rewarding read!

SPL meter should turn up tomorrow.

I am satisfied that a drum riser is the best route to go down as that's the loudest thing that will be played in the room...and of course not 130db : )

I will be looking for the ITU numbered document in the threads here to suss out what the best practical 2 Leaf MSM system might be...

Then I'll draw up my initial Mk 2 design : )

I look forward to designing it as right as possible first time, then tuning the room measuring regularly all the way!

Big Love to the forum and all who contribute and woe betide the spammers that seem to get in!

SPL meter should turn up tomorrow.

I am satisfied that a drum riser is the best route to go down as that's the loudest thing that will be played in the room...and of course not 130db : )

I will be looking for the ITU numbered document in the threads here to suss out what the best practical 2 Leaf MSM system might be...

Then I'll draw up my initial Mk 2 design : )

I look forward to designing it as right as possible first time, then tuning the room measuring regularly all the way!

Big Love to the forum and all who contribute and woe betide the spammers that seem to get in!

-

Purelythemusic

- Posts: 56

- Joined: Wed May 30, 2018 7:31 am

- Location: England, Bristol

- Contact:

Re: New build, isolation req. Control room enviroment

SPL meter arrived today.

Took readings at the proposed site at 9 and 10:20pm and average 45db : ) 40db at the quietist when the birds had gone to bed...still traffic noise from the motorway bridge some 2 miles away. It was set on A...forgot to compare with C...dammit

If my average drumming at loudest is around 110db then we're shooting for 65db.

I'm going to read the suggested different wall makeup's to find the ideal wall design to achieve that ambition.

I am used to building primarily in masonry Concrete blocks over here are not hollow and normal density is 1800 – 2100 kg/m3 so with a solid mass built blocks on their flat (215mm thick leaf) somewhere between 387 and 451.5 kg/m2 if I do: Density in kg/m3 then x by actual volume 0.215.

When I look at the density of Soundbloc gypsum board which is very readily available, it's weight is 10.8kg/m2 they say to establish a density you divide the m2 figure by the thickness in m, with a thickness of 12.5mm that works out as 848kg/m2 but surely one layer of plasterboard isn't going to be twice as massive as the equivalent in concrete blocks...what am I getting wrong mathematically here. Or is there another element unconsidered...the rigidity...if plasterboard is fixed at 400 centres, the middle can be subject to vibration...more so than block work.

Density = Mass/Volume

Either way, I'm happy to sacrifice some space to the gap between leaves to gain better isolation...it might be a bit tricky to calculate as one space on one wall is going to be about 1.5m wheras the other's a likely to be 150-200mm. I suppose assume they're all the lower 150-200, then the larger space is bound to be better right?

I also see alot of tape and jointing...we are used to skimming, or if better in some situations floating a backing coat of render then skimming. I assume skimming on the 3 layers of plasterboard on the inner leaf would if anything help with air tightness...providing all the caulking is done during the process in the recommended places?

Should this thread actually be in the design forum as it's not at the construction stage : ?

Took readings at the proposed site at 9 and 10:20pm and average 45db : ) 40db at the quietist when the birds had gone to bed...still traffic noise from the motorway bridge some 2 miles away. It was set on A...forgot to compare with C...dammit

If my average drumming at loudest is around 110db then we're shooting for 65db.

I'm going to read the suggested different wall makeup's to find the ideal wall design to achieve that ambition.

I am used to building primarily in masonry Concrete blocks over here are not hollow and normal density is 1800 – 2100 kg/m3 so with a solid mass built blocks on their flat (215mm thick leaf) somewhere between 387 and 451.5 kg/m2 if I do: Density in kg/m3 then x by actual volume 0.215.

When I look at the density of Soundbloc gypsum board which is very readily available, it's weight is 10.8kg/m2 they say to establish a density you divide the m2 figure by the thickness in m, with a thickness of 12.5mm that works out as 848kg/m2 but surely one layer of plasterboard isn't going to be twice as massive as the equivalent in concrete blocks...what am I getting wrong mathematically here. Or is there another element unconsidered...the rigidity...if plasterboard is fixed at 400 centres, the middle can be subject to vibration...more so than block work.

Density = Mass/Volume

Either way, I'm happy to sacrifice some space to the gap between leaves to gain better isolation...it might be a bit tricky to calculate as one space on one wall is going to be about 1.5m wheras the other's a likely to be 150-200mm. I suppose assume they're all the lower 150-200, then the larger space is bound to be better right?

I also see alot of tape and jointing...we are used to skimming, or if better in some situations floating a backing coat of render then skimming. I assume skimming on the 3 layers of plasterboard on the inner leaf would if anything help with air tightness...providing all the caulking is done during the process in the recommended places?

Should this thread actually be in the design forum as it's not at the construction stage : ?

-

Purelythemusic

- Posts: 56

- Joined: Wed May 30, 2018 7:31 am

- Location: England, Bristol

- Contact:

Re: New build, isolation req. Control room enviroment

Yep I misunderstood the MAM F equation...in IR-586 the equation makes much more sense and gives more predicted results:

Fmam= 60 or 43/ square root of (M1+M2 x d)

For arguments sake, with two 400kg/m2 mass walls with a cavity of 0.1m filled with fibreglass, it looks like Fmam would be 4.8hz so a peak would occur at twice that (if I understand other threads on this topic correctly) 9.61hz...

If I made the cavity 0.15 filled, predicted Fmam might be 3.92 x 2 = 7.85

I think the Mass of the plasterboard I worked out as per the gypsum website can't be comparable... I'll have to work that one out.

I need to look at those in more detail but it's some great info, thanks Stuart!

Fmam= 60 or 43/ square root of (M1+M2 x d)

For arguments sake, with two 400kg/m2 mass walls with a cavity of 0.1m filled with fibreglass, it looks like Fmam would be 4.8hz so a peak would occur at twice that (if I understand other threads on this topic correctly) 9.61hz...

If I made the cavity 0.15 filled, predicted Fmam might be 3.92 x 2 = 7.85

I think the Mass of the plasterboard I worked out as per the gypsum website can't be comparable... I'll have to work that one out.

I need to look at those in more detail but it's some great info, thanks Stuart!

-

Purelythemusic

- Posts: 56

- Joined: Wed May 30, 2018 7:31 am

- Location: England, Bristol

- Contact:

Re: New build, isolation req. Control room enviroment

Just worked out that I worked the gypsum board out by a factor of 10!!! 10.8kg/m2 / 0.125 is 86.4 not 864!!!

-

Purelythemusic

- Posts: 56

- Joined: Wed May 30, 2018 7:31 am

- Location: England, Bristol

- Contact:

Re: New build, isolation req. Control room enviroment

That was frustrating...just wrote a nice detailed post and it got lost....

Here we go again!

SPL at 10pm shows A weight of 38db, C weight of 45...low freq.

After reading IRC IR-586 and particularly P17. The 190/90 cavity wall with 155 air gap 65 Fibreglass seems to give large isolation. The conclusion explained how difficult predictable results would be due to attention to design etc...I imagine mortar drops are a culprit.

Mam F at this mass and with this air gap is nice and low.

If I were to want 100mm internal leaf, I'd have to build piers which seems like an awkward space to avoid. 140mm blocks wouldn't need piers at my size.

But, I think I've worked out 100mm block wall would be about 168kg/m2 in weight. With a density of 244kgm/m2. The same density could be achieved using 3 layers of soundbloc (actually better - each board has a density of around 84.8 * 3 = 254.4) At 31.8kg/m2 in weight, that wall seems a bit better to sit on a slab!

The tricky bit might be applying the same to the ceiling...I'll send and email to a structural engineer who I've worked with and who spec'd the steel on our current project what joist size would be needed to support 31kg/m2 of board over 4m span...might be 2"x10"s will do fine, or less as the dead load of a floor must be more than that.

I need to work out how to isolate the slab and therefore internal walls from the outer footings and therefore outer walls... I did read something Rod wrote on someone else's thread...sort of similar to how I had mentioned above.

Almost time to get drawing it out...

Here we go again!

SPL at 10pm shows A weight of 38db, C weight of 45...low freq.

After reading IRC IR-586 and particularly P17. The 190/90 cavity wall with 155 air gap 65 Fibreglass seems to give large isolation. The conclusion explained how difficult predictable results would be due to attention to design etc...I imagine mortar drops are a culprit.

Mam F at this mass and with this air gap is nice and low.

If I were to want 100mm internal leaf, I'd have to build piers which seems like an awkward space to avoid. 140mm blocks wouldn't need piers at my size.

But, I think I've worked out 100mm block wall would be about 168kg/m2 in weight. With a density of 244kgm/m2. The same density could be achieved using 3 layers of soundbloc (actually better - each board has a density of around 84.8 * 3 = 254.4) At 31.8kg/m2 in weight, that wall seems a bit better to sit on a slab!

The tricky bit might be applying the same to the ceiling...I'll send and email to a structural engineer who I've worked with and who spec'd the steel on our current project what joist size would be needed to support 31kg/m2 of board over 4m span...might be 2"x10"s will do fine, or less as the dead load of a floor must be more than that.

I need to work out how to isolate the slab and therefore internal walls from the outer footings and therefore outer walls... I did read something Rod wrote on someone else's thread...sort of similar to how I had mentioned above.

Almost time to get drawing it out...

-

Soundman2020

- Site Admin

- Posts: 11938

- Joined: Thu Aug 21, 2008 10:17 am

- Location: Santiago, Chile

- Contact:

Re: New build, isolation req. Control room enviroment

Great! So you have one part of the puzzle, right there: 45 dBC is the ambient level that you need to "quieter than". This is a control room, so the other part of the puzzle should be: "around 85 dBC average, 100 peak". Most engineers monitor at around 85 dBC or a bit less, but every now and then they do push it to 100 dBC or so, to "check the bass" in a loud playback. So you'll need at least 40 dB isolation, absolute minimum, and probably more like 50, to get your levels reasonably quiet outside. With 50 dB isolation, your normal 85 dBC level would be 35 dBC outside, which is basically silent, and for the brief 100 dB peaks, it would be around 50 dB outside, which is just slightly above ambient, and not really audible beyond a few meters.SPL at 10pm shows A weight of 38db, C weight of 45...low freq.

Right. PLus uneven mortar coverage, hairline cracks in the bricks and/or mortar, unsealed surfaces, and a few others.The conclusion explained how difficult predictable results would be due to attention to design etc...I imagine mortar drops are a culprit.

I assume you will be pouring a monolithic slab-on-grade foundation? If so, just make the foundation part wide enough to support BOTH walls. Problem solved. No piers needed.If I were to want 100mm internal leaf, I'd have to build piers which seems like an awkward space to avoid. 140mm blocks wouldn't need piers at my size.

I'm not sure what you mean by that: cinder block has a density of around 1700 kg/m3, so to get a surface density of 244 kg/m2 it would have to be about 14 cm thick, or to get 168 kg/m2 it would have to be about 10cm thick.I think I've worked out 100mm block wall would be about 168kg/m2 in weight. With a density of 244kgm/m2.

There seems to be some confusion here: It's not absolute density that you put into the equations: it is SURFACE density!The same density could be achieved using 3 layers of soundblo

The ABSOLUTE density of soundbloc is about 950 kg/m3, so the SURFACE density of a single 15mm panel is about 14 kg/m2. Three layers would have a surface density of about 42 kg/m2. But the actual weight of the wall depends on the length and height. For example, if the wall is 5m long and 2.5m high, it would have an area of 12.5m2. Multiply that by the surface density, and you get 525 kg. You'd need to add the weight of the framing, nails, insulation, electrical wiring, paint, etc. to get the total weight, but let's assume that it is 1000kg, to make the math easy. Since it is 5m long and the studs are 90mm wide, the area that is supporting all that weight is 5 x .09 = 0.45 m2. Therefore, the pressure that the slab must support is 1,000kg / 0.45m2 = 2,222 kg/m2. Call it 2,500 kg/m2, to be safe. In imperial terms, that's about 450 PSF. So your slab would have to be designed with that load in mind, for the location where the inner-leaf wall sits.

If you were to do the inner-leaf wall with cinder blocks, those are 200mm wide, so the math would be as follows: 1700 kg/m2 x 0.2 = 340 kg/m2 surface density. For the same hypothetical wall (5m long, 2.5m high), the total weight would be 5 x 2.5 x 340 = 4250 kg. Bearing area is 5m x 0.2 = 1m2 (the wall is 5m long and the blocks are 20cm wide), so the load on the slab is about 4,250 / m2. So roughly double the load of the soundbloc wall, but the surface density is eight times higher! (42 kg/m2 for 3 layers of soundbloc, vs 340 kg/m2 for cinder-block). So you would get much, much better isolation form the cinder block wall, and the load is only twice as much as the sounbloc wall.

It seems like there were some errors in your calculations...

If you do a cinder block wall, then you could easily do a beam-and-block ceiling to keep the same density.The tricky bit might be applying the same to the ceiling...

Why? you do not have a need for very high isolation. This is only a control room, so there won't be very high sound levels, such as from an acoustic drum kit. There's no need for an isolated slab here. A single monolithic slab will work fine, and is much easier, faster, and cheaper to do.I need to work out how to isolate the slab and therefore internal walls from the outer footings and therefore outer walls...

- Stuart -

-

Purelythemusic

- Posts: 56

- Joined: Wed May 30, 2018 7:31 am

- Location: England, Bristol

- Contact:

Re: New build, isolation req. Control room enviroment

Hi Stuart,

Thank you so much for your insight...I see surface density is the focus, that would make some more sense as a 100mm wall is going to be less flexible than 3 layers of soundbloc...but for it to have a decent surface density it would need to be rendered I assume, which I would anyway, then plaster it.

I think I've mislead by the subject title. As I mentioned in my introduction, though a while ago! I wanted a room that has the listening characteristics of a control room as I thought this is the best fit for a multi functioning room. Single track recording, mixing... I do want to be able to record drums at night time which is the most likely time I'll be able to! If I assume my average acoustic kit is at 110db then I'm designing for 65db attenuation, I think the floor flanking is an area worth separating. I will of course be building a riser for the kit.

I have clay soil here so I need to do strip footings down to maybe 1.2m, I was planning on building the outer block wall 215mm thick concrete block on the flat, then separate the ground bearing slab on grade by 25mm air gap and building 100mm thick concrete wall from that (providing the engineer is happy with that. I think the need for piers is actually for lateral load, wind, which an internal wall won't be subjected to much...and is also supported at the ceiling joists with strapping, so the engineer is likely to be happy with that.

I'm not sure if the cinder blocks are the same, maybe just the name has stuck over there but we don't really do blocks out of cinder anymore... breeze blocks they were called. We have aircrete, lightweight concrete blocks and normal concrete blocks (among others) I think the cinder block numbers you were referring to are comparable to the concrete blocks I'm planning to use.

I've assumed to apply similar logic to the ceiling as I have for the walls...except 2 x concrete block and beam ceilings does seem excessive and the footing detail would likely be more complex and costly than necessary. I propose a concrete block and beam outer roof, probably screeded and flat roofed. An inner ceiling build off the inner wall, not in any way connected to the outer roof structure, double boarded.

I'm going to have to get a planning application in soon as we're just about to get plastering on the extension, so we're only about 3 months away from possible digger in the ground again : ) We're restricted on the outer size so the inner design is not fixed which is just as well as the learning and designing is still near the beginning stages!

Thank you so much for your insight...I see surface density is the focus, that would make some more sense as a 100mm wall is going to be less flexible than 3 layers of soundbloc...but for it to have a decent surface density it would need to be rendered I assume, which I would anyway, then plaster it.

I think I've mislead by the subject title. As I mentioned in my introduction, though a while ago! I wanted a room that has the listening characteristics of a control room as I thought this is the best fit for a multi functioning room. Single track recording, mixing... I do want to be able to record drums at night time which is the most likely time I'll be able to! If I assume my average acoustic kit is at 110db then I'm designing for 65db attenuation, I think the floor flanking is an area worth separating. I will of course be building a riser for the kit.

I have clay soil here so I need to do strip footings down to maybe 1.2m, I was planning on building the outer block wall 215mm thick concrete block on the flat, then separate the ground bearing slab on grade by 25mm air gap and building 100mm thick concrete wall from that (providing the engineer is happy with that. I think the need for piers is actually for lateral load, wind, which an internal wall won't be subjected to much...and is also supported at the ceiling joists with strapping, so the engineer is likely to be happy with that.

I'm not sure if the cinder blocks are the same, maybe just the name has stuck over there but we don't really do blocks out of cinder anymore... breeze blocks they were called. We have aircrete, lightweight concrete blocks and normal concrete blocks (among others) I think the cinder block numbers you were referring to are comparable to the concrete blocks I'm planning to use.

I've assumed to apply similar logic to the ceiling as I have for the walls...except 2 x concrete block and beam ceilings does seem excessive and the footing detail would likely be more complex and costly than necessary. I propose a concrete block and beam outer roof, probably screeded and flat roofed. An inner ceiling build off the inner wall, not in any way connected to the outer roof structure, double boarded.

I'm going to have to get a planning application in soon as we're just about to get plastering on the extension, so we're only about 3 months away from possible digger in the ground again : ) We're restricted on the outer size so the inner design is not fixed which is just as well as the learning and designing is still near the beginning stages!

-

Purelythemusic

- Posts: 56

- Joined: Wed May 30, 2018 7:31 am

- Location: England, Bristol

- Contact:

Re: New build, isolation req. Control room enviroment

Nooo,

I just wrote a brilliant conclusion and crappy internet meant it has been lost...again!!!! Thankfully in the extension I'm running Cat6 cables everywhere through a patchbay.

Anyway, in summary, thanks Stuart I was working out surface density but didn't know it and was just getting the drywall calcs wrong.

Thanks also for showing the load for the footing.

I'll be back when the structural engineer advises on footing the concrete block inner wall. The architect is doing the basic drawings for planning approval.

I am pretty sure I am needing 65db isolation.

I don't think planning will let me build over 2.6m measured externally so I'm planning to build 550mm into the ground with long steps into the corridor to the studio. I'll do some attachments if I can!

Stuart, do you think I need not separate the two walls at the footing? it could be that the engineer wants them both on a wide strip footing.

Thanks so much!

I just wrote a brilliant conclusion and crappy internet meant it has been lost...again!!!! Thankfully in the extension I'm running Cat6 cables everywhere through a patchbay.

Anyway, in summary, thanks Stuart I was working out surface density but didn't know it and was just getting the drywall calcs wrong.

Thanks also for showing the load for the footing.

I'll be back when the structural engineer advises on footing the concrete block inner wall. The architect is doing the basic drawings for planning approval.

I am pretty sure I am needing 65db isolation.

I don't think planning will let me build over 2.6m measured externally so I'm planning to build 550mm into the ground with long steps into the corridor to the studio. I'll do some attachments if I can!

Stuart, do you think I need not separate the two walls at the footing? it could be that the engineer wants them both on a wide strip footing.

Thanks so much!

-

Purelythemusic

- Posts: 56

- Joined: Wed May 30, 2018 7:31 am

- Location: England, Bristol

- Contact: