If You have a Fiat Punto you cannot use a suspension system from a Scania truck, and vice-verse

Exactly. Good analogy, since that's exactly what it is: A shock absorber.

i am familiar with this procedure the thing is that i dont have the knowledge to do so.

Maybe your best bet would be to hire a contractor who will obey your instructions, and do it the right way, not his way. If he is willing to work your way, we can give you the instructions on what to do, and he can build it. As long as he agrees to just follow the plan, and not improvise himself, then that could work. Any good builder can do this, as long as he recognizes that acoustic construction is not like normal house or office construction, and he needs to take precautions that he would not normally have to do. It's an option that should be a lot cheaper than hiring an acoustic company to do it: As you say, they mark up all the materials, with a huge profit.

I don't want to imagine, but when we had an earthquake back in 1999 in my house nothing happened. The overall structure is VERY good.

And I bet that "nothing happened" to your house, because your walls in your house are firmly attached to your floor!

But that's not the case with your drum room. The walls and "floating" floor are not attached. When it comes to earthquakes, I have a bit of an advantage over some people: I live in Chile, which has the "honor" of having experienced the largest earthquake ever recorded in history, plus several more on the "top 20" list. We get quakes all the time, mostly small, some big. We had a magnitude 8.8 quake here in 2010, and it was pretty scary. Things move a LOT!

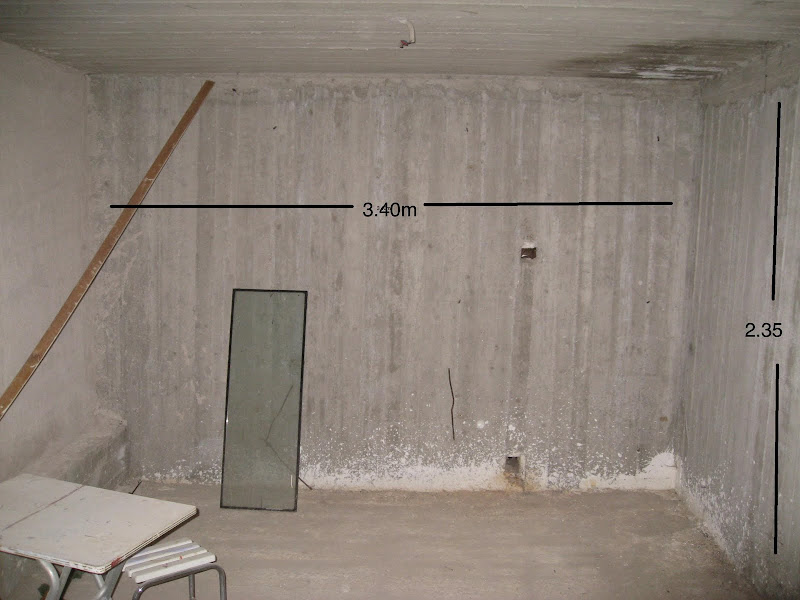

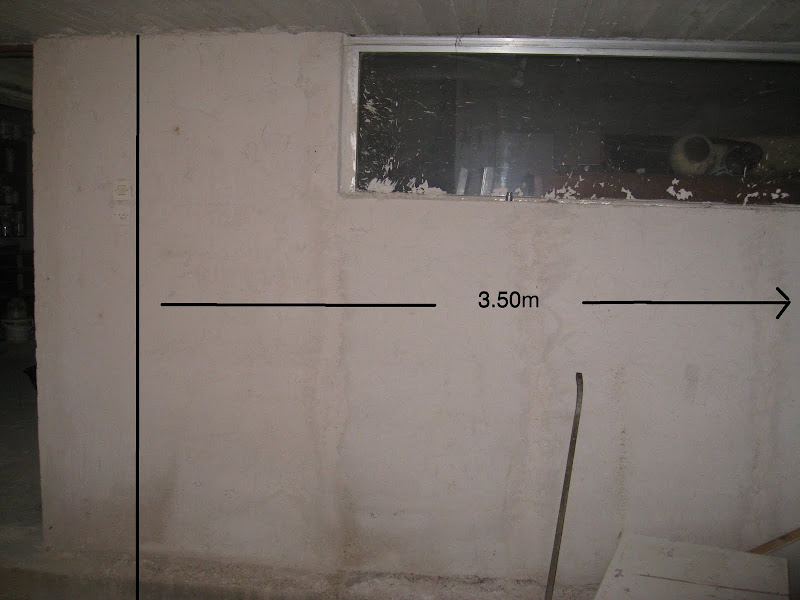

But all the structures I designed and built survived that, but only because I built them according to Chilean regulations: Here, walls must be bolted to floors. Looking at the photos you posted, your walls are resting on that "floated" floor, and nothing is bolted. In an earthquake, those will move differently. The room will be free to bounce up and down on the concrete floor, and also to slide side to side, since there is nothing to stop them doing that. You might not get quakes as big as Chile does, but in Greece you still get magnitude 6 and 7, which is PLENTY of shaking! I would not want to be inside that room in a magnitude 7 earthquake...

The guy on the 1st floor told me he heard the drums a bit more than before...

That's what I would expect, yes: your three-leaf walls are amplifying certain frequencies in the low end of the spectrum, whereas the original walls did not do that. Like I mentioned before, walls are tuned systems: they resonate at certain frequencies, set by the mass of the leaves and the size of the air gaps. Normally for a studio, the designer will choose a frequency that is much lower than the lowest frequency that needs to be isolated. So for example, if the room is for bass guitar and the lowest note is expected to be 30 Hz, for example, then the designer will specify the mass and air gap such that the resonant frequency "f0" of the wall is 15 Hz or lower. At 15 Hz the wall will not isolates, and will amplify. At 1.414 times f0 (21.2 Hz in this example) the wall starts isolating, and at 2 times f0, it isolates well. But if you put a third leaf inside the wall, it now has TWO fundamental resonant frequencies, not just one. They are called F+ and F-, and BOTH of them will be higher than the f0 of the original wall. So for example, they might end up at 25 Hz and 31 Hz, for example. In that case, when the bass player hits that low note at 30 Hz, the wall not only does not isolate, it can actually amplify the sound, making it louder on the other side.

I made some guesses about the air gaps and drywall density of your walls, and at a very rough calculation, F+ = 76 Hz, and F- = 54 Hz. So that wall does not isolate frequencies below 107 Hz, it isolates OK above 152 Hz and isolates well at 228 Hz. The fundamental frequencies of drums can be well inside that range, so I'm not surprised that the guy upstairs is now hearing things louder than before.

If you were to re-build that wall correctly, as a 2-leaf wall according your new plan with a total gap of 20 cm and 4 layers of drywall, then f0 = 13.9 Hz, the wall will isolate starting at 19.4 Hz, will isolate OK at 27.7 Hz, and will isolate really well above 41.6 Hz. Your drums will be very well isolated, no question at all. Even a six-string bass should be well isolated like that.

At the ground floor (my parents house) the living groom was vibrating. It wasn't like an earthquake but i could hear the bass and feel it a bit.

That is probably due to the drum-head "floating" floor: It clearly is not floating at all, and is resonating. It looks like it is 16mm plywood over a 4cm gap, which would make the resonant frequency somewhere around 100 Hz. But it isn't sealed, and there is insulation inside, so it will be a broadband resonator covering a range of frequencies around 100 Hz. That's right in the region where the kick drum and bass guitar live. I'm not surprised things were vibrating.

I have to tell you that the room IS NOT sealed right now. I have no doors etc. Vibrations are an effect of ground-born sound and not air-born but the fact that the room right now is not sealed has anything to do with the "buzz" noise?

The doors and seals probably won't have much effect, since the walls and floor are most likely flanking into the building itself, as well as perhaps being amplified by the resonance. In other words, the low frequency vibration is bypassing the attempt at isolation, and getting into the structure of the house. Once it is in the structure, there is nothing to stop it going anywhere in the house. Like you said, you can feel it in the building itself. Putting your door and the seals in place is not going to stop that. The door will only help to limit high frequencies a bit (cymbals), but the lows will still be felt n the house.

As Brien said in his post: the fact that you can feel the vibrations is proof that what has been built is not working.

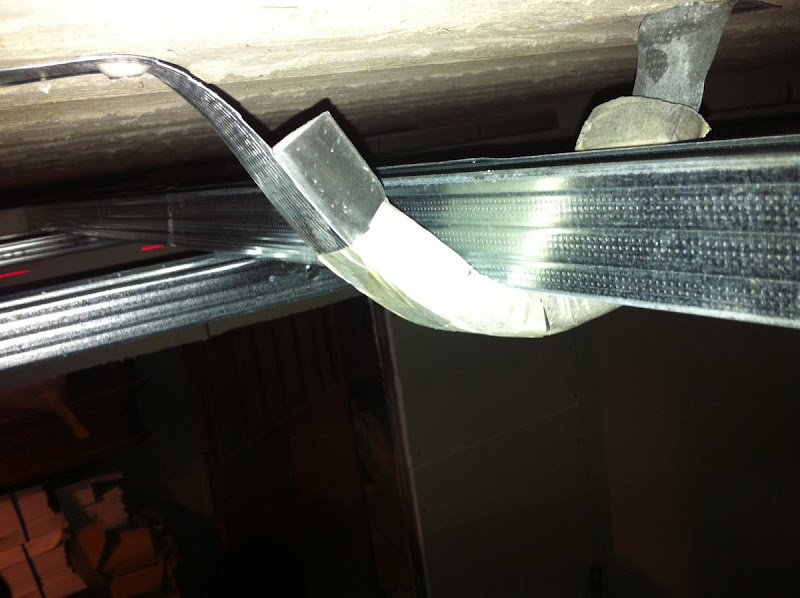

(check the pic "floating base of the drumset")

It looks like those guys are going to float their floor properly. They have the right hardware to do it, and since they are building on an upper floor, they most likely need to float. If they put enough mass on their floated floor, and have done their math correctly, then that should work. Those are proper isolation mounts, designed for very heavy, massive floors, which is the RIGHT way to do it! Their big problem is going to be those windows...

Concrete Walls with rock Wool, then 5-10cm air gap and then framing/Rock Wool and 4 layers of gypsum board.

Yes. The framing can only touch the floor. It must not touch the existing ceiling or the existing walls. Not even one single nail. This concept is sometimes called "room in a room" construction, since basically you are build a new and separate room inside an existing room, with no connections except the floor.

1) directly to concrete and then drum riser and something similar for the electric bass amplifier

Yes.

2) 10cm of rockwool 100kg/m3,

100 kg/m3 is too dense: it will not be good for low frequencies, and will probably flank. You need rockwool of around 50kg/m3. Or you could also use fiberglass of around 30 kg/m3.

But I would not do the floor like that. Just leave the floor as concrete, and do a drum riser, such as this one:

http://www.johnlsayers.com/phpBB2/viewt ... r+#p113503

Or this one:

http://sketchup.google.com/3dwarehouse/ ... 541410f02a

Simple, low cost, effective. It just sits on the plain concrete floor, and isolates the drums form the floor.

Ceiling

What about that...?

Same as the walls: You put new joists across the top of the new framing, and put your drywall on the joists. By very careful to make sure that the news ceiling does not touch the existing ceiling, or the existing walls. The new ceiling can ONLY touch the new walls, nothing else.

I mean if you had a company would you guarantee for much much better results? Would you give me my money back if your structure failed?

If you hired my company to design and build that room, then you bet I would guarantee it! I would give you written specifications up front, stating the expected isolation, and part of the fee would depend on those specs being met. If the actual measured isolation did not meet or exceed the spec, then you would not pay that part of the fee, and I would go home, sad and hungry...

That's what this company you hired should have done: a written guarantee before they start, stating what the isolation will be, in terms of how many decibels of TL you will get, or at least what the STC rating will be. Then if you measure the performance, and it does not meet the specs, either they return some of your money, or you don't pay them some of the agreed fee. That's they way I work. (But I don't live in Greece, so I can't do that for you! Pity... )

But you can still get a local builder to build it for you, as long as he follows instructions.

Just so that you feel more comfortable with the method we are telling you about, take a look at some of the studios that John has designed and built, and the comments from his customers after the studios are finished: they work! What I'm suggesting for your room is the same method that John uses for isolating his studios. It is a tested and proven method in use all around the world. But it's not just John: All the leading studio designers use the same method, because it works! It is the best way to isolate studios and rehearsals rooms at low cost. If you understand how it works, then it is easy to build.

There is also a huge amount of technical information on it, and on the level of isolation you can expect from different types of structures. There's a research document called IR-761 (and also IR-693 and IR-832) with hundreds of pages about different walls that were tested in an acoustic laboratory, showing how each one was built and how it performed. They actually built full size walls inside the lab, and tested them, one by one. All of the results are there, in IR-761.

There are three other documents, called IRC-169, IR-766 and IR-811 with the same information about floor isolation systems. Another one, IR-802, is specifically about impact noise on concrete slabs. Plus many more. And those are just a handful of documents from the National Research Council of Canada. There are many, many more from other places, all around the world. This is very well documented.

This is not guesswork and internet myth: this is the science of acoustics. The principles are well understood, and well documented. If you design it right, and build it carefully, then it works. The people doing your room right now are not using these principles, and that's why it is not working.

To be fair to the people who are trying to do your room, I think the issue is that they did a music room and thought they could also do a drum room the same way. But drums are different from most other musical instruments: Drums are the loudest of all, percussive, resonant, and put out very high levels of low frequency sound. They are the hardest of all instrument to isolate. What might work for isolating a music room in a school, will not work for drums: Two very different scenarios. Maybe their music room worked out well, but you can't build a drum room the same way you build a school music room: it won't work. Different thing entirely.

- Stuart -