Voice Booth Im building - HELP! Ventilation/Soundproofing

-

CidyZoo

- Posts: 58

- Joined: Mon Oct 22, 2007 2:01 pm

- Location: Michigan, USA

- Contact:

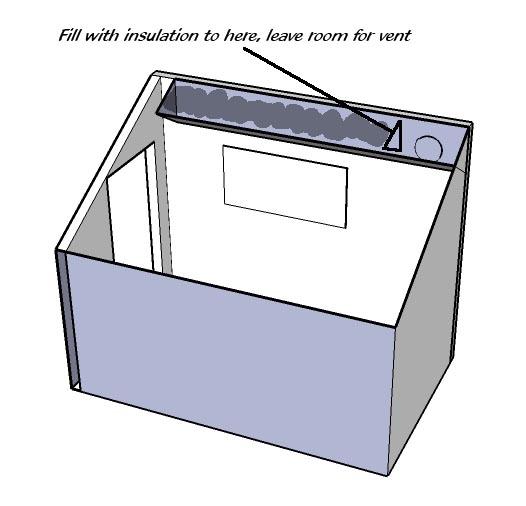

Where is the air gonna come in at?

Are you gonna have a fan pushing air into the plenum, or pulling air out?

You need to have an in-ie and an out-ie. That would make a big difference as to where the noise comes from. If it was gonna get hot in there, I think I'd suck air out the top and let it flow in passively at the bottom of the booth. Perhaps through another plenum like you have constructed already.

With the flapper mounted the direction you have it. It looks like you're gonna push air into the room at the top. You'll really need another flapper (oriented the other direction to allow the air to escape somehow. Otherwise the positive pressure that will build up in the room will restrict the airflow coming in.

Another option would be to have the fan (noise generating as it will be) located further away and "pulling" air through your booth. Use the plenum as you have it to stop sound from coming in to the booth (since it will have to make all those turns). Then have a fan (farther away from your booth) at the end of some flex duct pulling the air out. The general concensus I have read here is that you only need to make 180 degrees of bend (four right angle turns) to stop sound. I'm sure distance is a mitigating factor but maybe that would be a good solution for you?

It is posible that if you aren't really sealing "airtight" (which you would need to do to be isolating) that the booth will leak sufficient air through cracks that it won't be an issue.

Just a thought.

You see, my room has a small isolation booth too, and I am really curious how this is gonna work for you.

Whatever you do, I'm sure it will be far better than if you hadn't come here in the first place!

~ Bill

Are you gonna have a fan pushing air into the plenum, or pulling air out?

You need to have an in-ie and an out-ie. That would make a big difference as to where the noise comes from. If it was gonna get hot in there, I think I'd suck air out the top and let it flow in passively at the bottom of the booth. Perhaps through another plenum like you have constructed already.

With the flapper mounted the direction you have it. It looks like you're gonna push air into the room at the top. You'll really need another flapper (oriented the other direction to allow the air to escape somehow. Otherwise the positive pressure that will build up in the room will restrict the airflow coming in.

Another option would be to have the fan (noise generating as it will be) located further away and "pulling" air through your booth. Use the plenum as you have it to stop sound from coming in to the booth (since it will have to make all those turns). Then have a fan (farther away from your booth) at the end of some flex duct pulling the air out. The general concensus I have read here is that you only need to make 180 degrees of bend (four right angle turns) to stop sound. I'm sure distance is a mitigating factor but maybe that would be a good solution for you?

It is posible that if you aren't really sealing "airtight" (which you would need to do to be isolating) that the booth will leak sufficient air through cracks that it won't be an issue.

Just a thought.

You see, my room has a small isolation booth too, and I am really curious how this is gonna work for you.

Whatever you do, I'm sure it will be far better than if you hadn't come here in the first place!

~ Bill

Bill Toll ~ Cidy Zoo

-

PlatinumProd

- Posts: 29

- Joined: Sun Nov 25, 2007 1:53 pm

- Location: Raleigh, NC

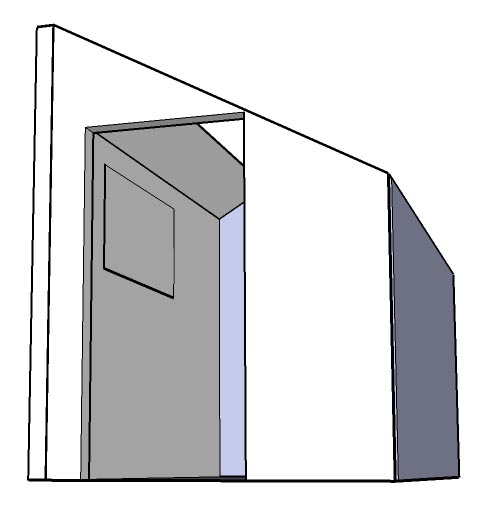

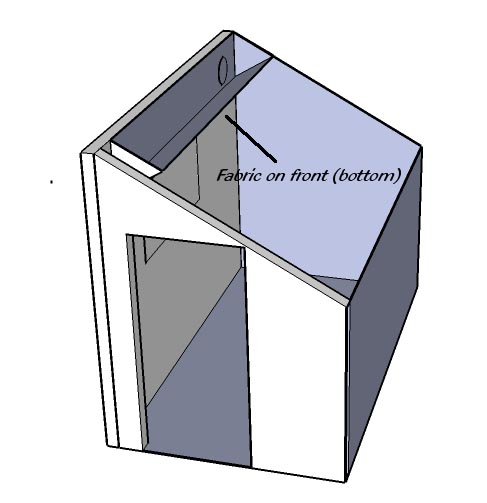

I thought of that, and felt such a huge bulge will be unsightly, even if functional. I think what I have in mind will isolate the sound sufficiently ... at least to being no more of a weak link than my door is.xSpace wrote:Platinum,

This design is going to lower the ability of your wall to isolate sound. Not having insulation as the rest of the wall makes this a weak link area.

If I had to do it, it would be a separate plenum box installed outside of my containment area rather then built into my isolation wall.

Just a thought,

Cidy Zoo is thinking along the same lines ... check out my response to his next post.

-

PlatinumProd

- Posts: 29

- Joined: Sun Nov 25, 2007 1:53 pm

- Location: Raleigh, NC

Bravo! You read my mind!CidyZoo wrote:I'm no expert, but it seems to me...hmmmm

Maybe if you really beef up the outside of that wall section (just over where your cavity is) with a couple extra layers of drywall.

Kind of overlap the outside wall and seal it really well. Add as much mass as you can to the exterior face. It won't cost you any interior room and since it seems like it's up off the floor, so you shouldn't loose any exterior floor space either.

It 'aught ta work if you ask me!

I felt the space in the wall was just too good a candidate for the space adjacent to the vent, but that if I add a layer of drywall, tape and shape a nice countour on the outside there, it would look presentable, consume less space AND serve as more sound isolation.

Have you seen this stuff? Volara?

http://foamforyou.com/volara_foam.htm

I thought if I sandwiched a sheet of Volara as a different kind of layer between the two outer drywall sheets, it would provide more blocking to the sound.

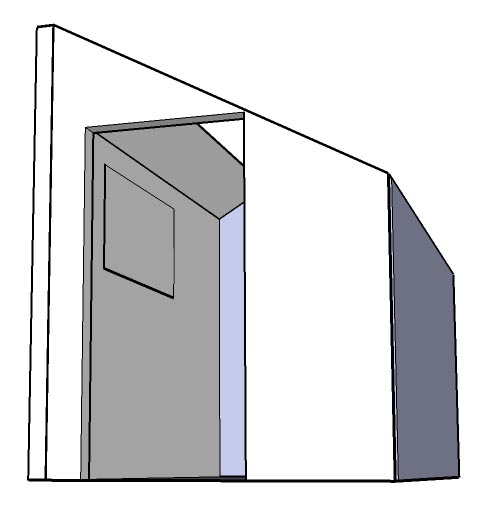

Interesting ... do you mean actually completely wrap the fiberglass insulation with a cloth? If so, what type of cloth? I heard if you compress the insulation any, it defeats the sound-dampening of it. Do you think I would compress it enough to encounter this condition?CidyZoo wrote: I know I'm repeating myself, but I'd cover the insulation on at least one of the interior walls with fabric and put extra layers of drywall on the outside of the same wall. Gives extra mass to at least one "leaf" and gets you a nice bass trap on at least one wall without loosing any space inside to wall mounted traps or foam. It won't be your weakest link for sound isolation since it wouldn't be any less transparent (sound-wise) than your door, the window or the plenum is.

If I'm going to do it, I have to do that today.

I appreciate your advice!CidyZoo wrote: I really wonder if the slanted roof section might be a good candidate for that treatment. You'd have to add layers to the undersideof your roof maybe, but it would stop the wierd reflection you're liable to get off that wall since it will be so close to you.

Like I said, I'm no expert though. Just trying to help!

~ Bill

I planned on putting a suspended section like this in the remotest top corner of the booth, above the window. I could hang it, experient some with the height or remove it easily if it is less desireable for any or all situations. Do you think this might help?

I plan to put one, horizontally, here:

Last edited by PlatinumProd on Sun Dec 30, 2007 11:24 pm, edited 1 time in total.

-

PlatinumProd

- Posts: 29

- Joined: Sun Nov 25, 2007 1:53 pm

- Location: Raleigh, NC

There is a heating/ac vent in the ceiling about three feet from the booth wall near the vent I placed. I plan to run a duct there. I already held the duct up to it, covering part of the first half of that vent. It pushed air into the booth from there rather nicely. I also figured doing it that way would satisfy some quirky requirements I heard about violating codes if you only vented the space with air from within the room.CidyZoo wrote:Where is the air gonna come in at?

Are you gonna have a fan pushing air into the plenum, or pulling air out?

You need to have an in-ie and an out-ie. That would make a big difference as to where the noise comes from. If it was gonna get hot in there, I think I'd suck air out the top and let it flow in passively at the bottom of the booth. Perhaps through another plenum like you have constructed already.

With the flapper mounted the direction you have it. It looks like you're gonna push air into the room at the top. You'll really need another flapper (oriented the other direction to allow the air to escape somehow. Otherwise the positive pressure that will build up in the room will restrict the airflow coming in.

Another option would be to have the fan (noise generating as it will be) located further away and "pulling" air through your booth. Use the plenum as you have it to stop sound from coming in to the booth (since it will have to make all those turns). Then have a fan (farther away from your booth) at the end of some flex duct pulling the air out. The general concensus I have read here is that you only need to make 180 degrees of bend (four right angle turns) to stop sound. I'm sure distance is a mitigating factor but maybe that would be a good solution for you?

It is posible that if you aren't really sealing "airtight" (which you would need to do to be isolating) that the booth will leak sufficient air through cracks that it won't be an issue.

Just a thought.

You see, my room has a small isolation booth too, and I am really curious how this is gonna work for you.

Whatever you do, I'm sure it will be far better than if you hadn't come here in the first place!

~ Bill

I picked up this inductor fan from Home Depot:

I figured, if necessary, I could switch this on at the exhaust I plan to rig at the opposite corner of the booth near the floor. If the inlet vent is not actively taking air into the booth, I plan to use this fan, away from the wall, but in my ducting, to force circulation. I was going to used coiled tubing with enough turns to stop sound, in the manner your described, and allow passive exhaust from there, but have forced pull if neccesary.

I hope all this effort I'm expending achieves some results.

If you guys can recommend some tests where I can quantify the effectiveness of my booth's isolation once I'm done, I'd appreciate it.

-

PlatinumProd

- Posts: 29

- Joined: Sun Nov 25, 2007 1:53 pm

- Location: Raleigh, NC

-

CidyZoo

- Posts: 58

- Joined: Mon Oct 22, 2007 2:01 pm

- Location: Michigan, USA

- Contact:

-

CidyZoo

- Posts: 58

- Joined: Mon Oct 22, 2007 2:01 pm

- Location: Michigan, USA

- Contact:

Guilford of Maine makes fire retardant cloth, but actually burlap works fine.

http://www.guilfordofmaine.com

search for FR 701® - 2100

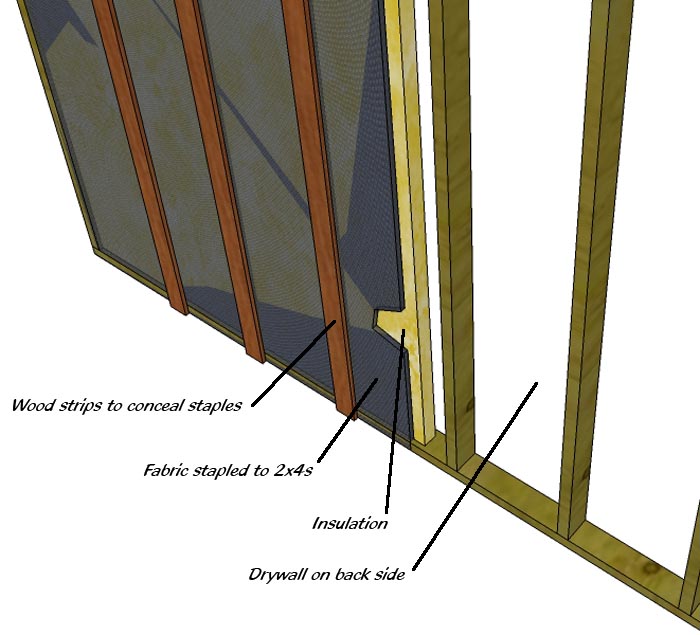

I am doing this in my booth and on my front walls:

I think foam directly on the slanted wall would give the best result. That would seem like the most logical area to make non-reflective. Anyone else have an opinion on that? (I'm no studio designer)

I understand your vent scheme now!

I read the review on that first fan, probably not a good choice. The other one says it is 49dB at lo speed, but says it only has one speed?

I don't know how dB translates into "sones", the fan I ordered was .7 sones, other not so quiet models were like 3-7 sones.

Rod G. had a note about sones vs dB ratings.

You'll find important info you should read today here:

http://www.johnlsayers.com/phpBB2/viewt ... roan+l100l

From what I understand Green Glue would be much better to sandwich between layers of drywall. Acoustic caulk is better than regular caulk also.

A mail order supplier is here (in Illinois, I ordered mine from them):

http://www.contractorstoolsupply.com/os ... -2591.html

The Volara site says "STC ratings / sound reduction numbers: 54 Decibel" someone with more knowledge needs to comment on that.

You can check your results with a Radio Shack dB meter, about $50. You'll want to have one when mixing to keep you monitoring levels at the proper volume (85dB) to prevent ear fatigue and give the flattest ear response.

http://www.radioshack.com/product/index ... age=search

I'll probably think of more stuff in a minute!

~ Bill

Bill Toll ~ Cidy Zoo

-

xSpace

- Moderator

- Posts: 3823

- Joined: Sat Aug 25, 2007 10:54 am

- Location: Exit 4, Alabama

- Contact:

xSpace wrote:Platinum,

This design is going to lower the ability of your wall to isolate sound. Not having insulation as the rest of the wall makes this a weak link area.

If I had to do it, it would be a separate plenum box installed outside of my containment area rather then built into my isolation wall.

Just a thought,

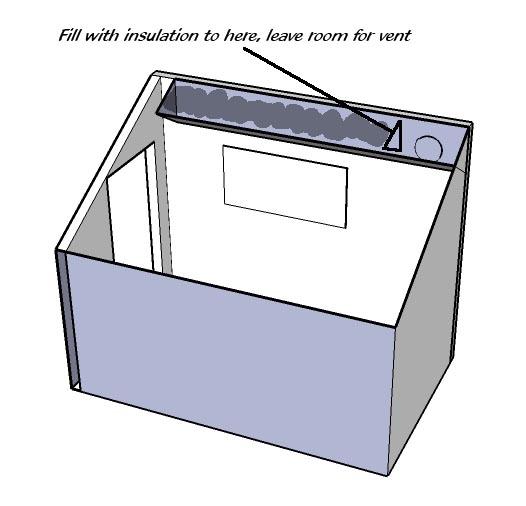

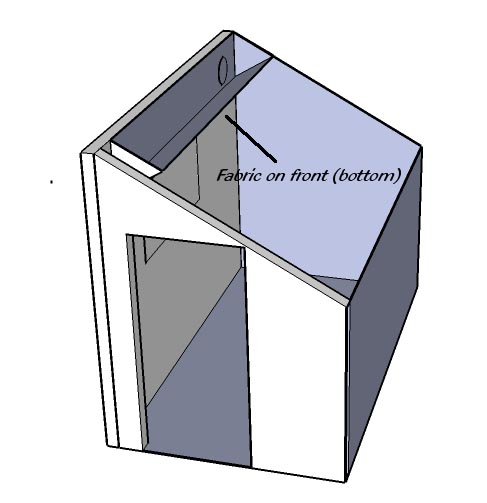

Or, in this area where the roof/ceiling line meets the wall and creates the obtuse angle, build a baffle system in there.

You would get rid of this angle, create a trap area and allow air in(maybe even out) all in one shot.

-

CidyZoo

- Posts: 58

- Joined: Mon Oct 22, 2007 2:01 pm

- Location: Michigan, USA

- Contact:

xSpave, good idea.

A corner trap built into that sharp angle at the ceiling/front wall corner (where your air vent is). you could build one (DIY, ie; covered in fabric) with some space that has no insulation and let the air in and out there.

That has got to be the best place for a bass trap (from what I understand, it's all about corners) and it would offer some needed absorption as well.

Kinda like the illustration here (only without the wood slats on the front and the MDF on the back). Perfect place for a couple pieces of OC703

http://www.johnlsayers.com/HR/index1.htm

In the ceiling/wall corner of course, not in a wall/wall corner as this drawing shows.

~ Bill

A corner trap built into that sharp angle at the ceiling/front wall corner (where your air vent is). you could build one (DIY, ie; covered in fabric) with some space that has no insulation and let the air in and out there.

That has got to be the best place for a bass trap (from what I understand, it's all about corners) and it would offer some needed absorption as well.

Kinda like the illustration here (only without the wood slats on the front and the MDF on the back). Perfect place for a couple pieces of OC703

http://www.johnlsayers.com/HR/index1.htm

In the ceiling/wall corner of course, not in a wall/wall corner as this drawing shows.

~ Bill

Bill Toll ~ Cidy Zoo

-

PlatinumProd

- Posts: 29

- Joined: Sun Nov 25, 2007 1:53 pm

- Location: Raleigh, NC

Cool!  Thanks for the drawings and additional advice!

Thanks for the drawings and additional advice!

It's too late to put my baffle in there. But, I can definitely still utilize this as a bass trap area.

Question I have is ... I ran pink noise and real time analysis in the space (at this point, of course, the window is not in and I haven't sealed everything ... nor put up my foam wall tiles). The bass frequencies are actaully attenuated in the room. I have a bump in the mid to high freq range, and not terribly radical, either.

I have a bump in the mid to high freq range, and not terribly radical, either.

Is it possible I may not even need a bass trap when I'm done?

It's too late to put my baffle in there. But, I can definitely still utilize this as a bass trap area.

Question I have is ... I ran pink noise and real time analysis in the space (at this point, of course, the window is not in and I haven't sealed everything ... nor put up my foam wall tiles). The bass frequencies are actaully attenuated in the room.

Is it possible I may not even need a bass trap when I'm done?

-

CidyZoo

- Posts: 58

- Joined: Mon Oct 22, 2007 2:01 pm

- Location: Michigan, USA

- Contact:

I am sure that you are correct with those readings.

In order for standing lo freq waves to develop you need a much bigger room. Bass freq have longer waves.

It's not so much that you are going to have such loud volume or sufficient volume of space for lo freq. room nodes to even develop. Hi freq are less of a problem with room nodes or nulls, however comb filtering is the greater problem.

I think we should have been calling the "bass trap" an "absorber". My inexperience I think had me using the wrong term. It would be a bass trap in construction (and location), but in such a small space it would function as a hi freq absorber. That would fight the comb filtering effect.

Somebody with experience might chime in and confirm what I am saying?

You will need the absorbers.

~ Bill

In order for standing lo freq waves to develop you need a much bigger room. Bass freq have longer waves.

It's not so much that you are going to have such loud volume or sufficient volume of space for lo freq. room nodes to even develop. Hi freq are less of a problem with room nodes or nulls, however comb filtering is the greater problem.

I think we should have been calling the "bass trap" an "absorber". My inexperience I think had me using the wrong term. It would be a bass trap in construction (and location), but in such a small space it would function as a hi freq absorber. That would fight the comb filtering effect.

Somebody with experience might chime in and confirm what I am saying?

You will need the absorbers.

~ Bill

Bill Toll ~ Cidy Zoo

-

PlatinumProd

- Posts: 29

- Joined: Sun Nov 25, 2007 1:53 pm

- Location: Raleigh, NC

Thanks for the input CidyZoo.

I finished walls except for front (by door) wall drywall and only did one pane. Cauclked as many air leaks as I could see. I have the one wall of drywall to put up, put the second pane of glass in, trim standard areas, seal door, add vent exhaust, paint, etc.

But, with one window in, I wanted to see what the noise reduction is. Closing the door was a NOTICEABLE difference!

SPL-8810, IEC 651 Type II, Slow dBA readings:

Ambient Noise (near computer): 41.5

Inside booth by same wall: 33.7

dB Reduction: 7.8

Should I be pleased so far?

I finished walls except for front (by door) wall drywall and only did one pane. Cauclked as many air leaks as I could see. I have the one wall of drywall to put up, put the second pane of glass in, trim standard areas, seal door, add vent exhaust, paint, etc.

But, with one window in, I wanted to see what the noise reduction is. Closing the door was a NOTICEABLE difference!

SPL-8810, IEC 651 Type II, Slow dBA readings:

Ambient Noise (near computer): 41.5

Inside booth by same wall: 33.7

dB Reduction: 7.8

Code: Select all

FreqHz Room Booth dB Redx %Redx

Ambt 41.5 33.7 7.8 18.8%

0031 48.6 35.4 13.2 27.2%

0063 54.1 37.1 17.0 31.4%

0125 78.5 55.5 23.0 29.3%

0250 85.1 60.1 25.0 29.4%

0500 85.5 53.7 31.8 37.2%

1000 90.0 42.0 48.0 53.3%

2000 90.0 46.7 43.3 48.1%

4000 92.8 45.7 47.1 50.8%

8000 91.4 44.7 46.7 51.1%

Last edited by PlatinumProd on Thu Jan 03, 2008 12:02 am, edited 2 times in total.

-

xSpace

- Moderator

- Posts: 3823

- Joined: Sat Aug 25, 2007 10:54 am

- Location: Exit 4, Alabama

- Contact:

-

CidyZoo

- Posts: 58

- Joined: Mon Oct 22, 2007 2:01 pm

- Location: Michigan, USA

- Contact:

It's getting too technical for me.

I am curious, Brien (xSpace), what seems odd about his measurements?

I would expect a greater dB reduction in the hi freq than in the lows, that part seems right doesn't it? Since they are much harder to "stop".

Do you mean the amount of reduction seems off?

I am not near to taking that kind of measurements in my rooms yet. But I wonder what I should be looking for. Since truthfully, I don't have a clue!

Doesn't standard house wall construction technique offer about a 20-30dB reduction in the "speech" frequencies area? So he is getting better in that area. As I would expect.

On a different note: I re-read your post. I think you were talking about using that top "corner" area as a plenum space? Is that what you meant? Sorry if I mis-understood.

That's a good idea too!

~ Bill

I am curious, Brien (xSpace), what seems odd about his measurements?

I would expect a greater dB reduction in the hi freq than in the lows, that part seems right doesn't it? Since they are much harder to "stop".

Do you mean the amount of reduction seems off?

I am not near to taking that kind of measurements in my rooms yet. But I wonder what I should be looking for. Since truthfully, I don't have a clue!

Doesn't standard house wall construction technique offer about a 20-30dB reduction in the "speech" frequencies area? So he is getting better in that area. As I would expect.

On a different note: I re-read your post. I think you were talking about using that top "corner" area as a plenum space? Is that what you meant? Sorry if I mis-understood.

That's a good idea too!

~ Bill

Bill Toll ~ Cidy Zoo

-

PlatinumProd

- Posts: 29

- Joined: Sun Nov 25, 2007 1:53 pm

- Location: Raleigh, NC

Are they odd? I think meter accuracy/sensitivity may be lacking in the lower frequency range . The meter is supposed to read 30~100 (Lo) and 60~130 (Hi). Or it may be the reference monitors (which I suspect) won't reproduce frequencies that low with as much volume. Those sounds were audibly low, volume-wise, though they did seem to carry into the room more.CidyZoo wrote:It's getting too technical for me.

I am curious, Brien (xSpace), what seems odd about his measurements?

I would expect a greater dB reduction in the hi freq than in the lows, that part seems right doesn't it? Since they are much harder to "stop".

No ... I'm just asking should I or would you be happy with the direction the amount of reduction is going. I don't know how they do their tests ... how loud and at what distance. But, percentage-wise, it seems comparable to some commercial booths costing $8,000 ~ $10,000, where my better numbers are.CidyZoo wrote: Do you mean the amount of reduction seems off?

Yes, he suggested making the plenum in that wedged space, but it's too late for me to do that now. I agreed it sounded like a good idea.CidyZoo wrote:

I am not near to taking that kind of measurements in my rooms yet. But I wonder what I should be looking for. Since truthfully, I don't have a clue!

Doesn't standard house wall construction technique offer about a 20-30dB reduction in the "speech" frequencies area? So he is getting better in that area. As I would expect.

On a different note: I re-read your post. I think you were talking about using that top "corner" area as a plenum space? Is that what you meant? Sorry if I mis-understood.

That's a good idea too!

~ Bill